Everything About Membrane Switch Over: A Comprehensive Guide for Beginners

Membrane layer buttons are necessary elements in modern electronic devices, using an unique user interface for customer interaction - membrane switch. Their layered building and construction, consisting of overlays and conductive traces, supplies functionality and durability. Unlike conventional mechanical switches, membrane switches provide a streamlined style and customizable options. Comprehending their crucial features and benefits can change item layout. The complexities of their application and layout factors to consider warrant additional exploration.

What Is a Membrane layer Switch over?

A membrane layer button is a kind of electric switch that consists of a versatile membrane layered over a printed motherboard. This design enables a streamlined and small interface, commonly made use of in various electronic gadgets. Membrane layer buttons are generally found in consumer home appliances, medical devices, and commercial equipment as a result of their resilience and resistance to environmental factors.The building generally consists of numerous layers, such as visuals overlays and glue backing, which offer tactile comments and secure the circuitry beneath. The procedure of a membrane layer button is started when stress is used to the surface area, completing an electrical circuit.These switches are valued for their flexibility, allowing customized styles and printed graphics that deal with specific interface. Their low-profile nature reduces room needs, making them excellent for applications where typical buttons might not fit. Generally, membrane switches supply a aesthetic and practical option for modern-day digital devices.

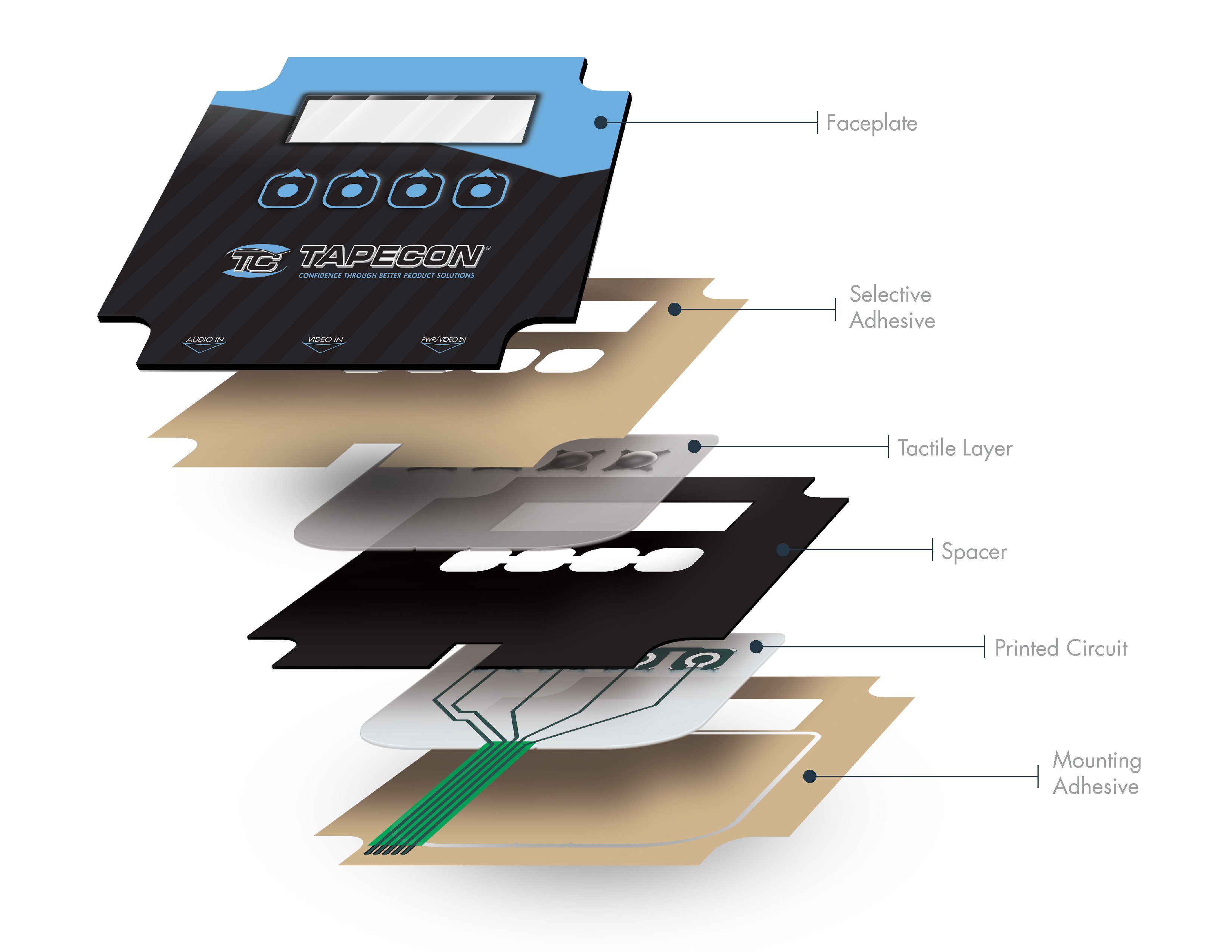

Trick Elements of Membrane Layer Switches Over

Membrane layer changes make up numerous key parts that add to their performance and performance. The leading layer, understood as the overlay, offers the customer interface and is usually published with graphics or signs. Underneath the overlay lies a spacer layer, which divides the conductive aspects and avoids unintentional activation. The next vital part is the graphic layer, which boosts aesthetics and ensures the resilience of the design.Conductive traces, typically made from products like silver or carbon, are printed on the circuit layer. When stress is put on the overlay, these traces come into call, completing the circuit. In addition, a backing layer supplies structural assistance and can be made from materials such as polyester or polycarbonate. With each other, these components produce a reliable, straightforward interface appropriate for numerous applications, from home devices to industrial tools. Comprehending these components is important for any person thinking about membrane layer button technology.

Exactly How Membrane Layer Switches Work

Recognizing how membrane changes feature is important for appreciating their prevalent usage in numerous devices. A membrane layer button runs through a series of layers, including a visuals overlay, spacer, and a circuit layer. When stress is put on the overlay, it compresses the spacer layer, enabling the circuit layer to make get in touch with and finish an electric circuit. This action sends a signal to the gadget, triggering a feedback, such as turning on a light or activating a function.Membrane changes can be created with numerous attributes, consisting of responsive responses, backlighting, and custom graphics, enhancing user interaction. Their building and construction permits a sealed style, securing the interior elements from dust, wetness, and pollutants. This toughness makes them ideal for varied applications, from consumer electronics to industrial equipment. Overall, the simplicity and effectiveness of membrane switches over add to their appeal in contemporary technology.

Advantages of Membrane Switches Over Mechanical Buttons

While mechanical buttons have actually long been a staple in numerous gadgets, membrane switches deal unique advantages that make them increasingly appealing. One significant advantage is their slim account, enabling more compact layouts and higher flexibility in product growth. Furthermore, membrane switches attribute an uniform surface area, which enhances aesthetic charm and streamlines cleaning, making them appropriate for atmospheres where hygiene is critical.Another advantage is their resistance to dirt and dampness. Unlike mechanical switches, which can be endangered by ecological elements, membrane layer buttons offer a sealed user interface that safeguards versus pollutants - membrane switch. Furthermore, membrane switches generally have a longer life-span because of fewer relocating parts, leading to enhanced longevity and reliability.Cost-effectiveness is likewise a notable advantage, as membrane layer switches can be generated wholesale with reduced manufacturing prices. These aspects incorporate to position membrane buttons as a practical option to typical mechanical options in different applications

Usual Applications of Membrane Changes

Membrane layer buttons are widely utilized in different markets, specifically in customer electronic devices and commercial control panels. In consumer gadgets, they give a smooth, straightforward interface, while in industrial setups, they boost longevity and performance. Comprehending these applications highlights the convenience and practicality of membrane buttons in modern-day technology.

Customer Electronic Devices Devices

As consumer electronics remain to progress, membrane layer switches have ended up being a prominent option for a range of devices as a result of their convenience and streamlined layout. These buttons are frequently located in smartphones, tablet computers, and remote controls, where room is limited and looks issue. Their reduced profile and personalized layouts permit makers to produce easy to use user interfaces that boost the general individual experience. Additionally, membrane switches are frequently used in appliances such as microwaves and coffee machine, supplying intuitive control options while resisting dampness and dirt. The toughness and integrity of membrane layer switches make them see this website suitable for day-to-day customer items, guaranteeing longevity and regular performance. In general, their combination in consumer electronic devices reflects a mix of capability and try here modern-day design.

Industrial Control Panels

The applications of membrane layer changes extend past customer electronics, locating significant usage in commercial control panels. These buttons are favored for their durability and resistance to rough settings, making them suitable for manufacturing and procedure control settings. They supply a reputable interface for drivers to control equipment, monitor procedures, and change setups. Membrane switches can be tailored to fit particular functional demands, integrating functions like backlighting and tactile responses, improving customer experience. Their low-profile layout enables for assimilation into different tools, while their capability to endure spills, dirt, and severe temperatures assurances long life. Generally, membrane layer switches add to effective and safe operation in industrial applications, demonstrating their convenience and efficiency in requiring settings.

Considerations for Designing Membrane Layer Switches

When developing membrane switches, choosing the appropriate materials is necessary to assure durability and functionality. Furthermore, understanding layer configuration methods can substantially influence the switch's performance and individual experience. These considerations play an important role in producing trusted and reliable membrane layer button styles.

Material Choice Significance

Material selection plays an important role in the design and functionality of membrane layer buttons. The selected materials directly influence the button's toughness, responsive action, and total visual. Secret considerations include the substratum, which have to give architectural stability while permitting adaptability, and the visuals overlay, which needs to be resistant to put on and environmental factors. Conductive products must ensure dependable electric efficiency, while adhesives should offer solid bonding without jeopardizing the button's procedure. Additionally, compatibility with making procedures and end-user environments is vital; products should hold up against differing temperatures, moisture levels, and chemical direct exposure. Eventually, appropriate product selection not just enhances the membrane layer switch's efficiency but additionally adds to its long life and user satisfaction, making it an important aspect of the layout process.

Layer Setup Techniques

Frequently Asked Concerns

For How Long Do Membrane Layer Switches Normally Last?

Membrane layer switches normally have a lifespan of 1 to 5 million cycles, depending upon use and ecological conditions. Variables such as style high quality and operating frequency considerably influence their durability and general efficiency long life.

Can Membrane Layer Changes Be Personalized for Specific Designs?

Membrane buttons can undoubtedly be customized to accommodate details styles, permitting diverse forms, colors, and performances. This versatility makes it possible for makers to tailor these buttons to satisfy distinct visual and operational needs successfully.

What Materials Are Made Use Of in Membrane Switch Over Building?

Membrane buttons are typically built making use of materials such as polyester, polycarbonate, and glue layers. These materials supply adaptability, resilience, and resistance to ecological variables, guaranteeing the switches operate efficiently in different applications and problems.

Are Membrane Switches Over Resistant or water resistant to Dampness?

Membrane layer buttons can be developed to be moisture-resistant, making use of specialized finishes and materials. Their water-proof capabilities depend on construction top quality and details applications, making it vital to evaluate demands for optimal efficiency in various environments.

Exactly How Are Membrane Changes Fixed if Damaged?

Repairing damaged membrane switches generally entails changing the impacted layer or circuit. Specialists may likewise apply conductive sticky or use specialized repair work sets, guaranteeing performance is brought back without complete replacement of the entire button assembly. Unlike traditional mechanical buttons, membrane layer switches offer a sleek style and customizable alternatives. A membrane layer button is a kind of electric button that consists of an adaptable membrane layer layered over a printed circuit board. The procedure of a membrane layer switch is initiated when stress is applied to the surface area, completing an electrical circuit.These buttons are valued for their flexibility, making it possible for custom-made designs and published graphics that cater to details individual interfaces. While mechanical buttons have long been a staple in several gadgets, membrane layer changes deal distinct benefits that make them increasingly appealing. Membrane layer switches commonly have a longer life expectancy due to less moving components, resulting in boosted toughness and reliability.Cost-effectiveness is also a notable benefit, as membrane layer switches can be generated in bulk with lower production costs.